Some Basics on U.S. Manufacturing

In ways American manufacturing is in decline. In other ways, it has never been better

Is American manufacturing in decline? The answer is: “Yes” if you mean US manufacturing’s shrinking percentage of GDP, if you mean the declining number of manufacturing jobs, or if you mean America losing its lead in being the World’s largest manufacturer. The answer is “No” if you mean America’s rising manufacturing output” or if you mean the rising amount of value-added dollars American manufacturing produces. Confusing? Let’s break this down:

Manufacturing as a % of GDP

Yes, American manufacturing has declined as a percentage of GDP. Just like every other Western Country.. America is not special with its manufacturing percentage decline. Manufacturing going down and services going up is quite normal for advanced economies. North America, Europe, and Oceania have become service-based economies as the third stage of development. Just like China underwent its tier 2 stage development from agriculture to manufacturing. (China is now approaching tier 3. China’s manufacturing percentage has been declining as well. ) As manufacturing work becomes more automated or assembly work gets outsourced, less jobs are needed for manufacturing, and more workers end up going to services (healthcare, financial services, technology, consulting, law, education).

Manufacturing Output

By manufacturing output, America is nearly historic highs(we still haven’t recovered from the Great Recession though, See Graph #2 below). In my opinion, it is accurate to say is that America has declined from being the #1 or even #2 manufacturer in the world due to global competition, and that American manufacturing jobs have declined in America due to automation.

America losing the World Lead

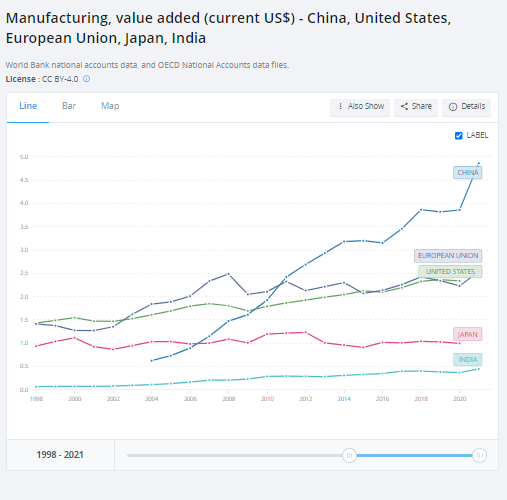

So in absolute terms, American manufacturing is the almost highest its ever been (and if we just look at dollar amounts, American manufacturing is at peak levels). But when we look relatively compared to the World, America is #3, China produced nearly $5T in value added manufacturing, while European Union slightly beats America for the number 2 slot. (EU: $2.54T with 450M people, America: $2.5T with 330M people). China produces almost double EU and America combined. When people say American manufacturing has declined, what they should say is America is no longer #1 in the World. Also, Japan produces $1T and India at $450B.

Post WW2 to roughly 2002, America was the largest Manufacturer on earth. Why did why decline? America had an artificial advantage post-WW2: it’s competition was non-existent due to WW2 destroying European cities while continental America was untouched. America was competition free until the 1960s. From 1945-1960 the world either didn’t participate in global trade (Communist Bloc), had its industrial base blown up (Western Europe & Japan), or was an unindustrialized cash crop exporter at time of independence/too poor at the time (India, Malaysia, The Continent of Africa, China). Quite literally after WW2, Western Europe had food shortages, refugees camps, damaged railways, bridges, and docks. That’s why the Marshall Plan came into being. Europe was so destroyed, that it was quite impossible for them to maintain their colonial empires. Just as an example to illustrate how big an advantage America had, in 1950s, American cars firms (Ford, GM, & Chrysler) produced 80% of the World’s Cars due to lack of competition. Due to low competition, America lived in a somewhat mythical world where a white man can finish high school, work a tire factory job in Ohio and support a family of four. That world was never sustainable. Eventually manufacturing jobs moved from Western Mass, Upstate NY, and the Midwest to the south due to South having less unionization, lower wages, and a lower rate of industrialization (The South industrialized slower due to it relying on exporting cash crops from its slave, and then sharecropping economy). Then in 1960s,West Germany, Japan, and other nations started to become global competitors. By 1990 with Germany & Japan BMWs, Audis, Mercedes, Volkswagens, Nissans, Hondas, and Mitsubishis captured 40% of the global market, while America shrank. Now as of 2021, China is the largest car manufacturer in the world by far.

There’s similar stories you can say with other sectors of the economy. Boeing was uncontested in aircraft manufacturing until Western Europe made Airbus came in the 1970s. By 1980s, some parts of American manufacturing were losing so badly to the regional integration from Western Europe and Japan-Taiwan-South Korea manufacturing that they either died, advanced their technology, looked to Mexico, or American Private equity firms had to flush firms with debt to survive or die. Examples include Uniroyal Goodrich Tire Company in 1985 (tire manufacturing) and RJR Nabisco (processed food and tobacco) in 1988.

American Manufacturing Employment

Now let’s move on to employment, if you see the graph below, it's true that fewer people do work in manufacturing. It is true that we have a decline in factory workers. Manufacturing jobs peaked in the late 1970s. As of right now, manufacturing only contributes 11% of American GDP. The components of American GDP that are bigger than manufacturing($2.5T) are the finance, insurance & real estate sector ($4.9T), professional & business services (accounting, law, consulting, etc.) ($3T), Government ($2.8T), and manufacturing comes at #4. (Information Tech is #8 at 1.3T).

So if you look at the employment graph and the value added dollar graph, we’ll be able to see if manufacturing has gotten more productive or not. In Graph 3, in 1998, America produced $1.4T in manufacturing output with 18M workers (in Graph 4) that’s roughly ~$78K per worker. In 2021, we produced $2.5T with 13M workers, that’s ~$192K per worker. If we are producing almost 2x more with 70% of the workers that’s due to efficiency gains with technology and automation. Just to hit this point home, in 1980, American steelmakers needed 10.1 manhours to produce one ton of steel. By mid 2010s, it took 1.5 man hours. Some mini-mills only need 30 minutes. American steel used to use integrated steel mills by manually feeding iron ore and coal into blast furnaces. Now we have super efficient, automated mini mills with electric arc furnaces to turn scrap metal into steel. There used to be 650K steel jobs in 1953. By mid 2010s, America has 143K steel workers. Also, the type of manufacturing labor in America has changed. The normal manufacturing worker has evolved from 1980 to 2000 to 2020. We don’t need people screwing wrenches but we need mechanical engineers doing research and development for drones, advanced robotics, control systems for weapon systems, automated 3D printing, and self driving cars. The Top Manufacturing employers in the United States are Apple (electronics), GM & Ford (cars), and Cardinal Health (pharmaceuticals). The biggest issue in manufacturing, in my opinion, is not that we need jobs to “come home”. But rather, we need more engineers and highly skilled technicians to do the jobs of the future.

Is Globalization Good or Bad?

I think people need to remember that trade brings people out of poverty and gives us cheaper goods. The average Chinese worker was starving and poorer than Sub-Saharan Africa in the 1960s, a concept unthinkable now to a millennial. In 1960, your average American made 24x the average Chinese worker (adjusted for purchasing power). By mid 90s, the average Chinese person was richer than the average Black African. Now as of 2021, the Average American makes 3.5x the average Chinese worker. Globalization has lifted hundreds of millions of Chinese out of poverty, and China has shrunk the wage gap between them and Americans.

Is Protectionism Good or Bad?

Protectionism makes sense to protect jobs for national security concerns. But protecting inefficient industries (like American steel jobs), means Americans pay more for those goods, hurting poor people the most. That’s the annoying thing about globalization, it distributes the gains but concentrates the losses. We don’t see how much more expensive our industrial or consumer goods would be if we didn’t have globalization, but we do see run down manufacturing plants in Akron, Ohio. Here’s an example of what protectionism does: The American Steel Workers Union lobbied the Obama administration to slap a 35% tariff on Chinese tires (that means when American car firms buy from tires suppliers from China, Ford or GM has to pay a 35% tax when they buy that good. The idea of a tariff is to a good prohibitively expensive to make American firms and households buy local goods instead. But if Ford or GM still buys that tire, they will most likely increase the price of their car to pass the costs on to consumers. The Petersen Institution for International Economics’ analysis shows that Obama’s 2009 tariffs on Chinese tires saved 1200 jobs. However, if tires were never put on in the first place and if American firms just bought Chinese tires without having to buy Chinese tires with a tariff or buy American tires, then American consumers would have, in total, saved $1.1B on their new car purchase. That’s a $920K cost to American consumers per job saved or an added $7.33 cost to the American consumer for that one tariff. ($1.1B steel cost/150M workers = $7.33 ). Tariffs concentrate the gains, but distribute the losses.

But we have just scratched the surface of globalization. Next time I want to talk about how not all companies went global, but how more companies went regional.

A great vid on American trade:

Nice overview of the stats on American manufacturing. It is good to step back and take a broad view.